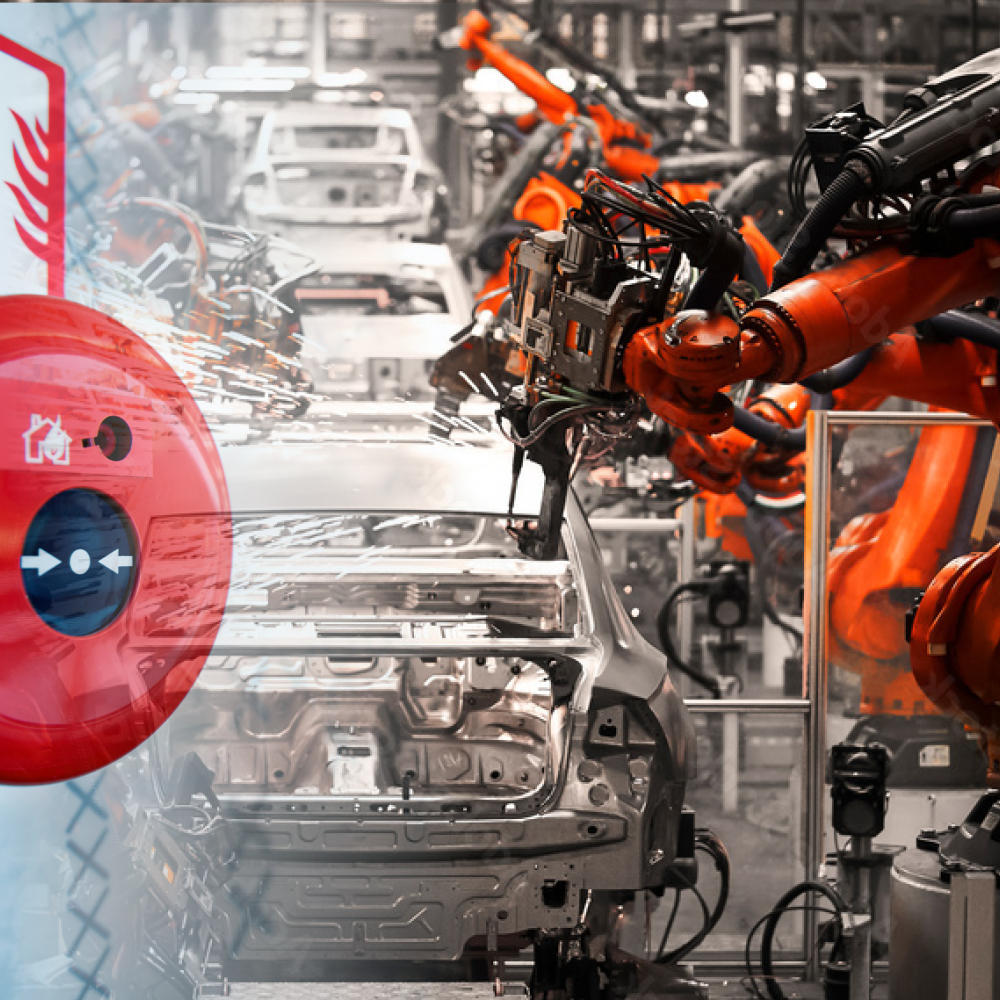

This is how the fire alarm signaling system is made for the BMW Group Plant Debrecen

BMW Group is one of the world's most renowned premium automobile and motorcycle manufacturers. According tot he plans, manufacture begins in 2025 on the Debrecen plant site, covering over 400 hectares. The construction is carried out in compliance with the highest safety standards, with a particular focus on fire protection. In our article, we will showcase how TELL, one of the leading domestic security technology development and manufacturing groups, is involved in the comprehensive establishment, implementation, and 24/7 operation of the fire alarm system.

CHALLENGES OF FIRE ALARM

With the advancement of the construction industry, there is a growing need for new and innovative methods in the field of fire protection. BMW Manufacturing Hungary Kft. has recognized this need and, in the interest of safe operations, equips its facilities and manufacturing units exclusively with modern and reliable fire protection solutions. They diligently and systematically prepare to ensure that from the very first steps, production is coordinated and efficient. This way, they aim to produce vehicles in the Debrecen factory that meet the high standards worthy of the BMW brand.

In line with this, TELL Group, a significant player in the domestic and international security technology market, was entrusted as a direct contractual partner for the implementation of the fire alarm transmission system. One of BMW Group's fundamental principles is to engage local experts and companies whenever possible to deliver various solutions. TELL came into the company's focus due to its references and expertise: they offer their own developed and manufactured products that are utilized in both the public and private sectors, as well as within the corporate sphere.

Implementing a fire alarm transmission system on a facility of such a significant scale presents substantial challenges. Fire protection is of paramount importance in industrial facilities, especially in the case of a factory of similar size and complexity, where numerous buildings, equipment, and consequently, multiple fire control centers are present.

Therefore, rapid and accurate fire alarm signaling and response time are of paramount importance, as we are talking about human lives.

One of the primary challenges of the project is that the optical network for the continuously expanding manufacturing halls is still under construction. Due to its absence, a centralized fire alarm transmission system cannot be implemented. This issue has compelled the developers and fire safety experts to find a solution that, despite this, enables 99.99% availability, secure, and efficient operation and maintenance. Fire safety authorities enforce strict approval procedures, and without the presence of fire alarm signaling, they do not grant occupancy permits.

To solve the emerging challenges, TELL group offered a unique, complex and integrated system solution. They undertook the full implementation, installation and commissioning of the system, as well as its continuous operation, which means a long-term and complex process. All of this was offered to BMW Manufacturing Hungary Kft. as part of a leasing framework, providing a sustainable solution for fire protection.

DETAILS OF A PROJECT: FIRE PROTECTION FROM THE FIRST MINUTE

Let’s get to know the technical details. Each object in the factory has one or more fire centers. These centers receive signals from smoke and fire detectors, but they are not capable of relaying signals themselves. This requires a reliable remote monitoring communicator, specially developed for fire alarm control panels. Using the DUALCOM 4G certified communicator for fire alarm control panels, TELL quickly and reliably transmits events from the fire center via a redundant GSM network to the local fire department operating in the factory area, TELL's remote monitoring system and the PAJZS system of the National Disaster Management Authority.

As part of the comprehensive solution, the company used the DUALCOM KIT, which included the signaling device, two SIM cards, the battery, and the power supply. They placed significant emphasis on ensuring uninterrupted power supply, as continuous operation in this context can be life-saving. Additionally, TELL provides 24/7 technical support, further enhancing the system's availability, reliability, and efficiency.

In line with the ongoing construction and commissioning activities within the factory premises, TELL ensures the establishment of fire alarm monitoring for each individual object and building, fully complying with regulatory requirements. Additionally, it's worth noting that the Hajdú-Bihar County Disaster Management Directorate utilizes the same fire alarm monitoring system that the company successfully implemented within the factory premises, similar to other county-level Disaster Management Directorates.

In addition, cooperation and partnership are also key elements in the success of the project. The TELL group works closely with its subcontractors. The long-lasting and successful professional relationship made it possible for the installation and operation of the system to be carried out effectively and efficiently in this case as well.

The success of the project shows that it is possible to coordinate safety and efficiency, even in a factory area of this size and complexity, by undertaking integrator tasks, using self-developed, manufactured devices, and complex expertise. The comprehensive system solution developed and implemented by the TELL company can provide inspiration for future projects, how to reliably handle the challenges of fire protection in the rapidly changing industrial environment. All of this has been accomplished by Hungarian professionals, with the support of adequate professional knowledge and references.